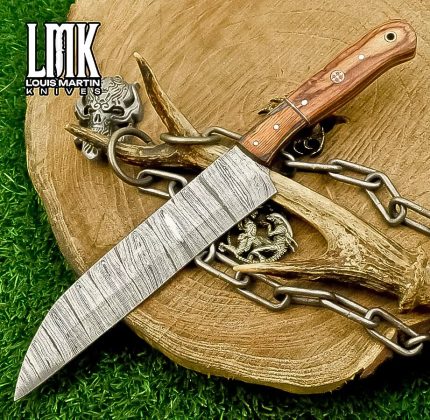

From the Forger:

At our workshop, we take immense pride in crafting authentic Damascus steel knives that surpass mere acid etching. Here’s an overview of our Damascus steel-making process:

- Material Selection: We meticulously combine 1095HC and 15N20 carbon steel nickel for our blades. 2. Layering: The chosen steels undergo repeated heating and folding to achieve a remarkable 384 layers. 3. Acid Burn: Following the layering process, the blade is treated with acid, revealing the brilliant nickel shine and a dark gray hue in the high carbon steel, thereby showcasing the stunning Damascus patterns.4. Blade Finishing: Concurrently, we expertly sharpen the blade’s edge, transforming the acid-treated edge into a striking satin finish.

Our unwavering commitment to preserving the authenticity and craftsmanship of Damascus steel ensures that each knife in our collection showcases intricate layers and delivers exceptional performance.

Overall Lengths: 13”

Blade Length: 8”

Blade Material: Layered Damascus 1095 HC & 15N20 Nickel Carbon Steel

Layers: 384

Hardness: 54-58

Acid Burned

Oil Quenched

Hand Forged

Handle Length: 5”

Handle Material: Antler

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Related products

Bowie D2 15 12 Wood

Bowie D2 16 11 Rody Stan Wood & Brass Guard

Bowie D2 19 12 Etched White Camel Bone & Hardwood

Chef Knife 13 Damascus Walnut

CUSTOM HANDMADE 1095 HIGH CARBON STEEL HUNTING Bowie KNIFE WITH WOOD HANDLE.

1095 High-carbon steel is formed using conventional techniques. It needs more force than low-carbon steels to perform this process. It is welded using all welding techniques. It is pre-heated at 260 to 315°C (500 to 600°F) and post-heated at 648 to 788°C (1200 to 1450°F). It is hardened at 899°C (1650°F). It is then quenched in oil, followed by tempering. The cutting edge of knives is hardened by heating and quenching to maintain the steel's toughness.

Reviews

There are no reviews yet.